Every DÖTCH piece begins its journey in our dedicated workshop, where craftsmanship meets tradition. We work with skilled artisans who bring decades of leather working expertise, ensuring every bag is made with the utmost care, precision, and pride.

Phase 1

Handmade to Order

Unlike mass-produced goods, each DÖTCH product is handmade to order. This not only ensures the finest attention to detail but also promotes sustainable practices by reducing unnecessary stock and waste.

Phase 2

Premium Materials

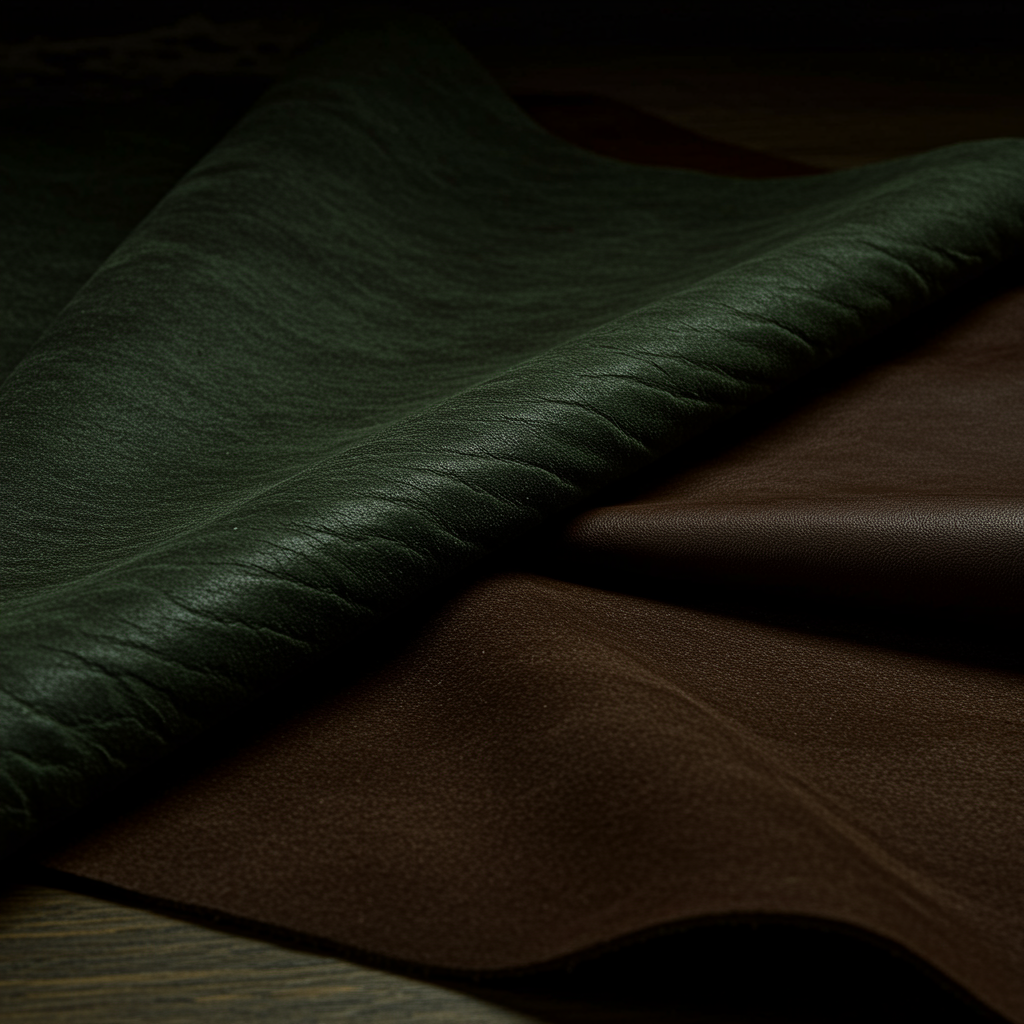

We source only the highest quality, full-grain buffalo and cowhide leathers, chosen for their durability, natural character, and ability to age beautifully over time. Combined with solid brass hardware and reinforced stitching, every piece is built to last for years of use.

Phase 3

A Fusion of Heritage & Modern Design

Our workshop blends traditional leather-craft techniques—hand cutting, burnishing, and stitching—with modern innovations in design. The result is a collection that embodies both timeless elegance and contemporary functionality.

Phase 4

A Human Touch in Every Detail

From the first cut of leather to the final polish, our artisans pour passion into every step. Subtle imperfections in the grain are celebrated as part of the leather’s natural character, making each DÖTCH creation truly unique and personal.

DÖTCH is more than just a place of production—it is where our philosophy comes to life: Luxury, sustainability, and craftsmanship, woven together to create products with purpose.